FST

Published in 21/01/2018

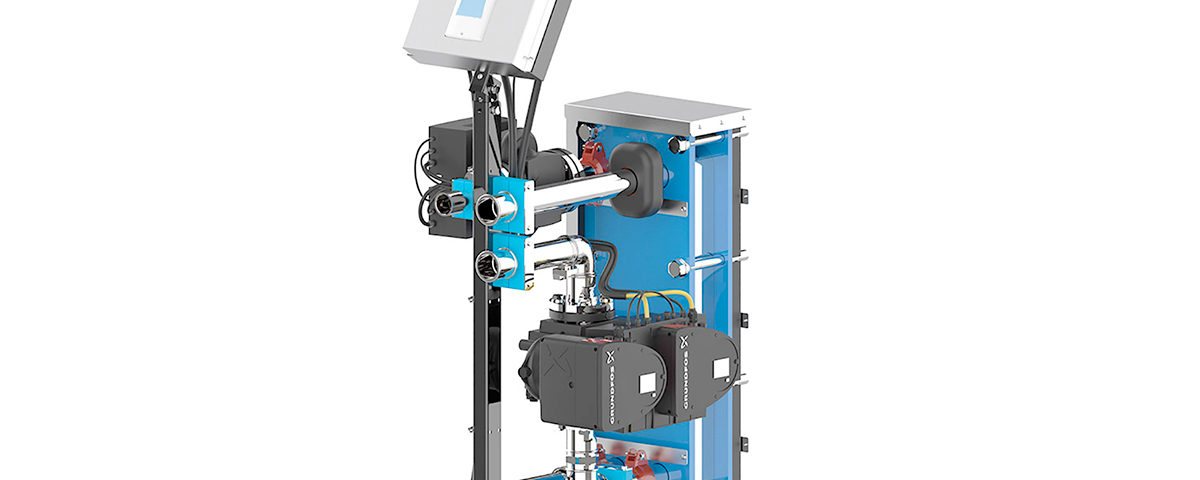

FST semi-fast DHW heater

FST semi-fast DHW heater

FST semi-fast DHW heater

The FST DHW heaters are pre-assembled units which, in combination with a storage tank of a suitable size, allow you to quickly produce and store large quantities of domestic hot water at a pre-set temperature.

All in a compact space thanks to the ultra-compact monobloc structure and the space-saving dimensions of the control unit.

Through the user-friendly, intuitive electronic control panel, it is possible to control the device by setting a variety of factors, such as the temperature setpoint, pump operation and the programming of the anti-legionella treatments.

Available in 150 standard combinations, the FST can cover a wide range of requirements in terms of power (from 55 to 700kw). They are also designed to be used in a modular format which allows you to increase the power, for example, by adding exchanger plates.

FEATURES

Power range

From 55 to 700 kW

Plate heat exchanger

Inox AISI 316

Maximum pressure

10 bar

Maximum temperature

95° on the primary circuit, 90° on the secondary

Versions

5 (1P+1P, 2P+1P, 2P+2P, 0+1P, 0+2P)

Usage

Rapid DHW productionS

VERSIONS

The FST units are available in 5 main versions which differ by the number and position of the pumps and circulators

| Model | Circulator set-up | Size |

|---|---|---|

| 1P+1P | semi-fast DHW heaters with single circulator on the primary and secondary circuit | From 55 to 700 |

| 2P+1P | semi-fast DHW heater with double circulator on the primary circuit and single on the secondary circuit | From 55 to 700 |

| 2P+2P | semi-fast DHW heaters with double circulator on the primary and secondary circuit | From 55 to 700 |

| 0+1P | semi-fast DHW heaters with double circulator on the primary and secondary circuit | From 55 to 700 |

| 0+2P | semi-fast DHW heaters with double circulator on the primary and secondary circuit | From 55 to 700 |

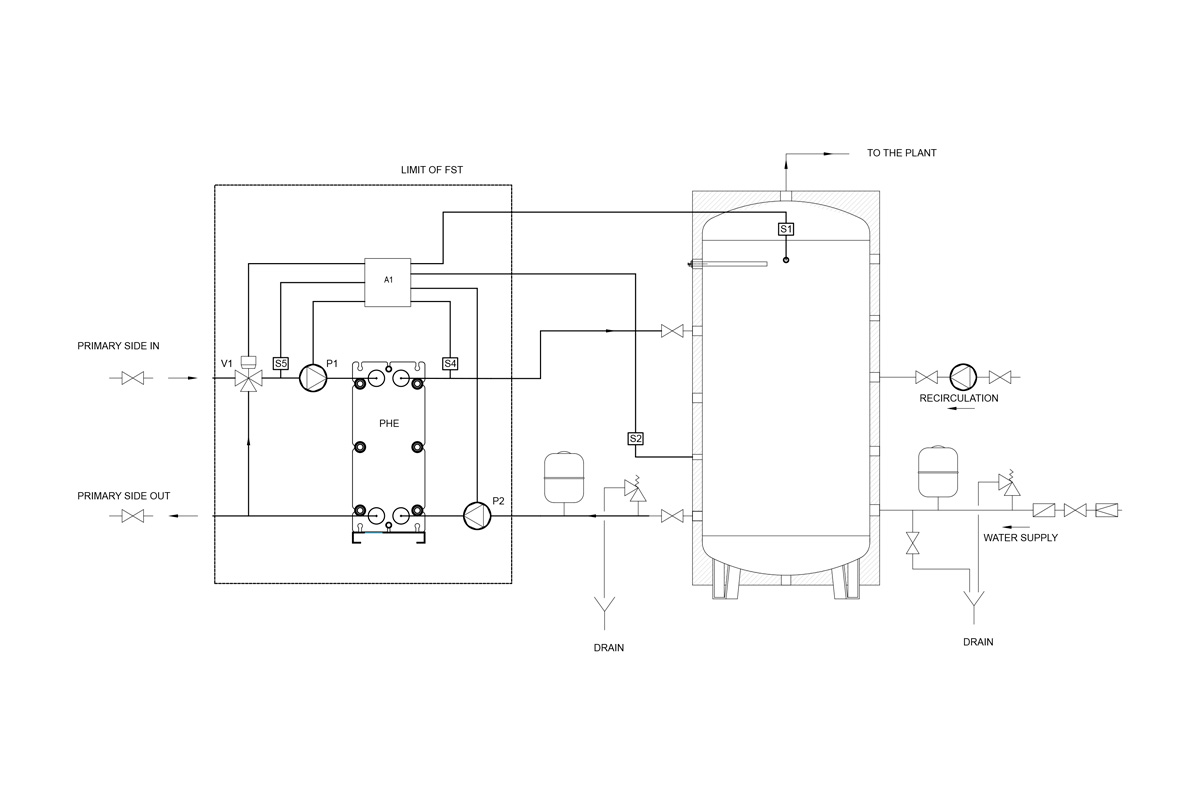

1P + 1P Version

| PHE | Plate exchanger |

| P1 | Pump on primary side |

| P2 | Pump on secondary side |

| V1 | 3-way mixing valve (optional) |

| S1 | Temperature probe (supplied unassembled) |

| S2 | Temperature probe (optional) |

| S4 | Temperature probe |

| S5 | Temperature probe (optional with V1) |

FST 1P+1P

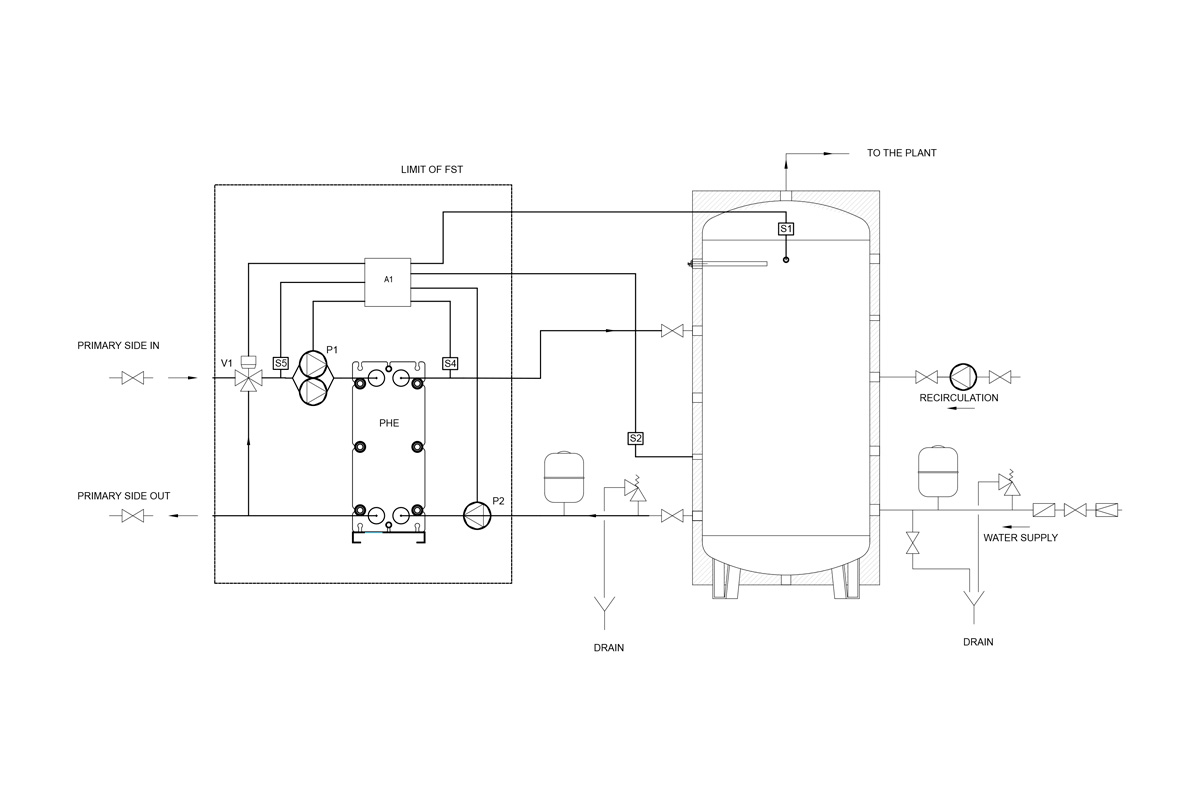

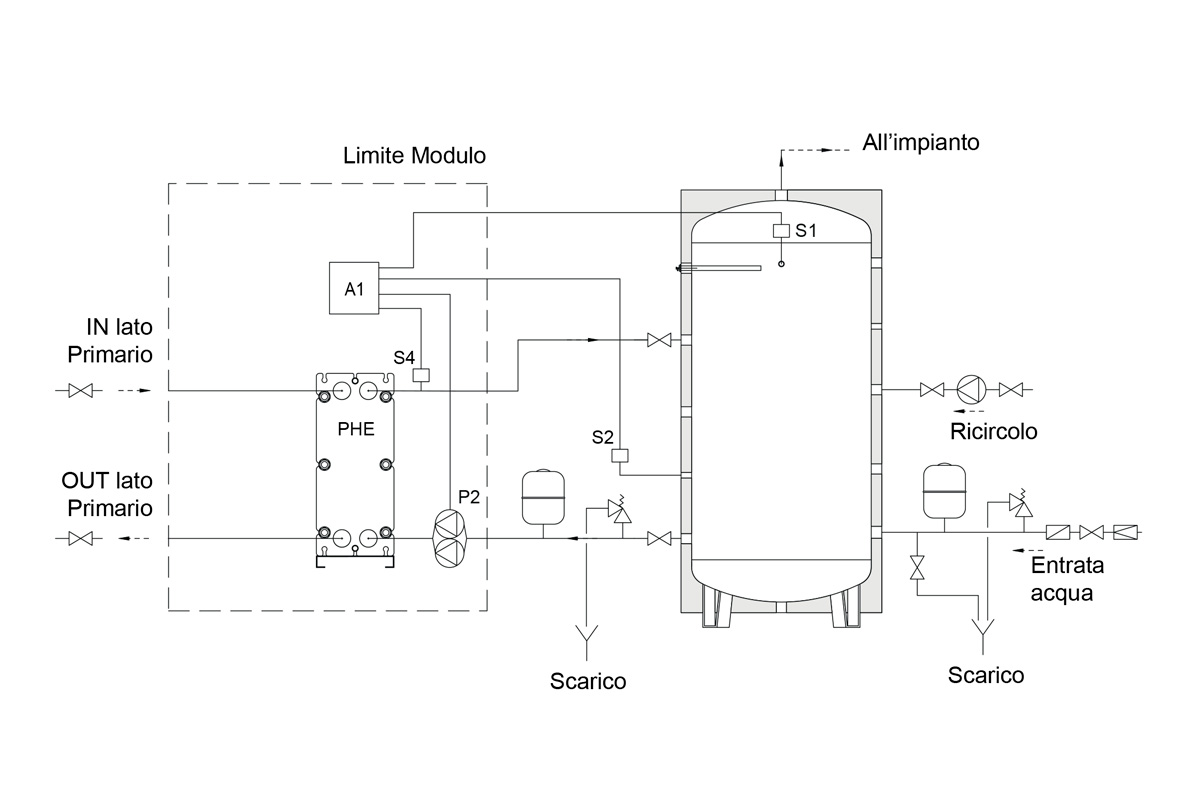

2P + 1P Version

| PHE | Plate exchanger |

| P1 | Pump on primary side |

| P2 | Pump on secondary side |

| V1 | 3-way mixing valve (optional) |

| S1 | Temperature probe (supplied unassembled) |

| S2 | Temperature probe (optional) |

| S4 | Temperature probe |

| S5 | Temperature probe (optional with V1) |

FST 2P + 1P

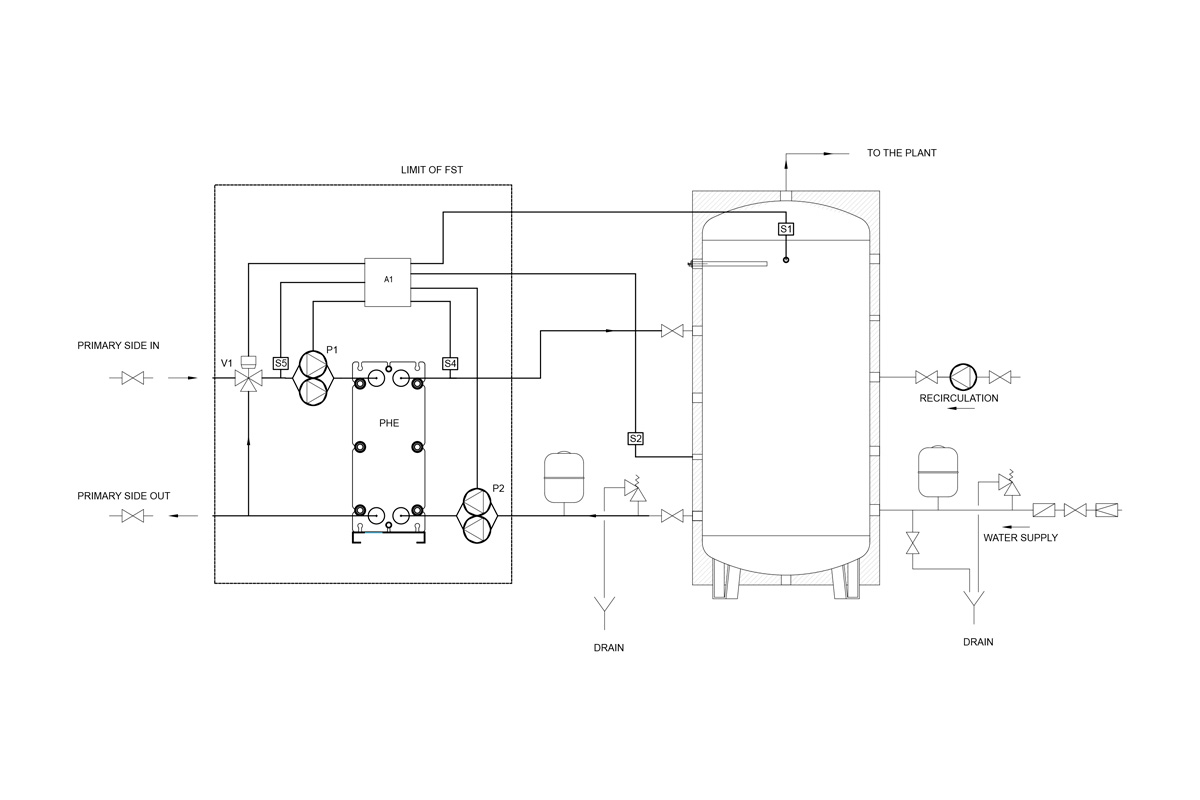

2P + 2P Version

| PHE | Plate exchanger |

| P1 | Pump on primary side |

| P2 | Pump on secondary side |

| V1 | 3-way mixing valve (optional) |

| S1 | Temperature probe (supplied unassembled) |

| S2 | Temperature probe (optional) |

| S4 | Temperature probe |

| S5 | Temperature probe (optional with V1) |

SET 2P +2P

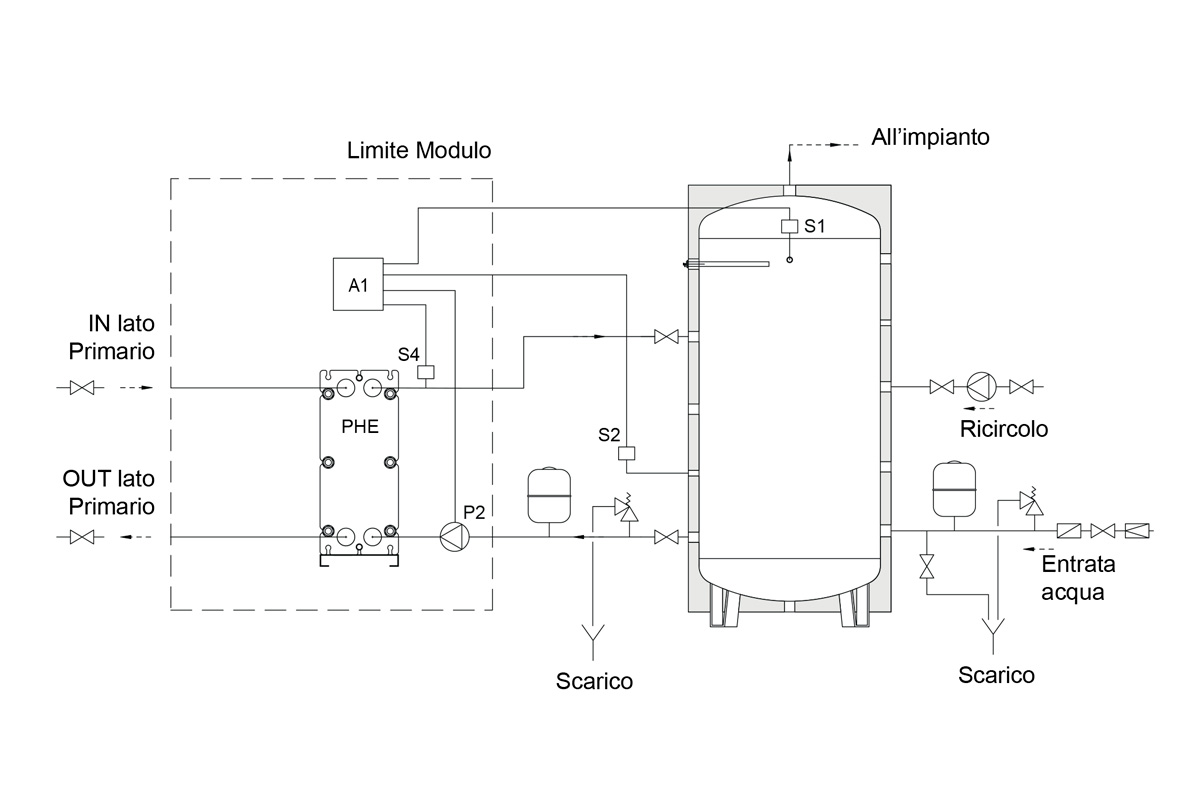

0P + 2P Version

| PHE | Plate exchanger |

| P2 | Pump on secondary side |

| S1 | Temperature probe supplied unassembled |

| S2 | Optional temperature probe |

| S4 | Temperature probe |

Versione 0P+2P

0P + 1P Version

| PHE | Plate exchanger |

| P2 | Pump on secondary side |

| S1 | Temperature probe supplied unassembled |

| S2 | Optional temperature probe |

| S4 | Temperature probe |

Versione 0P+1P

The benefits

The main benefits of the FST unit are:

| Compact size | Monobloc with space-saving adjustment control panel. |

| Easy to maintain | Handy component access. |

| Modularity | Possibility of increasing the power by adding exchanger plates. |

| Convenient to use | Adjustable control panel for easier use. |